As a leading semiconductor distributor, WT is committed to providing cutting-edge products and exceptional solutions to tens of thousands of customers and end-users worldwide, overcoming various challenges. However, facing the increasingly severe climate change, WT is committed to taking responsibility, actively responding to climate risks, and seizing the opportunities that arise. We will continue to deepen our expertise in green design, develop energy-saving products and solutions, optimize energy efficiency, and reduce the carbon footprint of our customers and end-users. At the same time, we will work with supply chain partners to respond to various advocacy initiatives and jointly implement the four major green design goals of energy conservation, waste reduction, resilience, and efficiency.

• Extreme weather event

• Climate regulatory and policy

• Market demand change

• Technological innovation and iteration

• Supply chain disruption

• Energy conservation

• Waste reduction

• Resilience

• Efficiency

• Strengthen supply chain resilience

• Design resilience applications

• Society safer and resilience

• Green design advocacy initiative

• Collaborates with suppliers and customer

• Industry-academia collaborations

▲ WT is committed to advancing clean technology and green design, guided by three core values and four action strategies

Addressing climate risks and opportunities

WT has identified five main climate risk factors:

(1) Extreme weather event risk: Property damage or transportation disruptions caused by natural disasters such as typhoons, hurricanes, floods, droughts, high temperatures, and heavy snow.

(2) Climate regulatory and policy change risk: Laws or standards introduced by countries or regions to reduce carbon emissions and waste, which may affect production costs and require products to meet stricter standards after changes.

(3) Market demand change risk: Increased demand for energy-efficient and high-performance products due to rising environmental awareness, leading to the inability to continue selling or using existing products.

(4) Technological innovation and iteration risk: Economic and equipment investment in developing new technologies and components, requiring significant professional manpower and resources for research and development.

(5) Supply chain disruption risk: Production or supply chain disruptions caused by climate change, such as resource scarcity affecting production or transportation, electricity, or water resources, leading to disruptions throughout the supply chain.

In addition to identifying the aforementioned risks, WT actively invests resources to address climate opportunities. In green technology innovation, WT has facilitated the adoption and implementation of technologies such as green energy and energy storage within the industry chain through long-term development and promotion. Regarding the issue of improving energy efficiency, WT continues to accelerate research and development and increase investment in research related to high-energy-consuming industries such as power supplies, motors, and artificial intelligence. In emerging markets such as environmental monitoring and climate early warning, or in response to supply chain challenges posed by extreme climates, we also maintain close collaboration with customers and suppliers to enhance supply chain resilience. We continuously and actively participate in green initiatives, promote environmentally friendly electronic components, and develop the green product market, enabling WT to make significant contributions.

Enhancing green design

Green design is not only a key to addressing climate change, but also a significant opportunity for industrial development. As a leading semiconductor distributor and a key player in the electronics industry, WT actively invests in technological innovation, market expansion, and application deepening of green design, while integrating clean technology and green thinking into every design. From the selection of green materials for semiconductor components and supply chain management to the sustainable architecture, component durability, and energy-efficient applications of product design, we are committed to extending product lifecycles. With the responsibility of a semiconductor distributor, WT contributes to the electronics industry’s response to climate change through green innovation.

WT continues to collaborate with suppliers, prioritizing products with green design concepts (such as those assessed to reduce resource usage or chemical substance content by 10% or more).

We focus on green applications and clean technology (such as clean transportation in electric vehicles or autonomous driving systems), and continuously improve energy efficiency in data centers, communication systems, public facilities, and other areas. In addition to continuously introducing more energy-efficient solutions, we also propose designs that benefit the environment and human health and safety in diverse fields such as industrial automation, infrastructure, and medical and healthcare.

Serving tens of thousands of customers globally, WT analyzes different regions, markets, and applications, not only strengthening economic influence, but also collaborating closely with suppliers on green design and clean technology-related applications, promoting industry sustainability and green innovation.

Strengthening social resilience

WT provides high-quality products from leading suppliers to serve tens of thousands of manufacturers worldwide, and continuously builds strategic partnerships with leading vendors and customers. We not only strengthen supply chain services and improve inventory management to address supply chain disruptions caused by extreme weather, but also actively increase R&D investment in green design. In these green designs, we act as a bridge for multi-party collaboration between industry, academia, and research, and propose excellent solutions. This not only enhances the technological development of our customers but also cultivates talent, improves industrial innovation capabilities, and accelerates green transformation. These actions not only strengthen the resilience of the supply chain and industry but also make society safer and more progressive.

To design resilience applications, extreme weather may cause disruptions in electricity, communication, transportation, and other areas. WT, in its research, development, and promotion, has emphasized the importance of resilience in various applications. For example, we have invested in the research and development of technologies such as renewable energy and grid-tied systems in power supply systems, battery safety and power management in energy storage systems, and the design of solutions for early warning, protection, and backup in response to power outages or quality degradation in different application areas.

In strengthening system resilience, we emphasize redundant design and flexible architecture, enhance the ability to respond to faults or risks, and continuously improve scalability. WT uses a modular architecture to make design redundancy and maintenance simpler and easier, and can shorten the replacement or response time in the event of a fault or risk. Modular design also has many advantages when functional upgrades are required, which not only ensures that the system is not interrupted due to upgrades, but also disperses development resources, reduces vulnerability risks, and eliminates safety hazards, further strengthening application resilience.

Energy Storage System (ESS)

Composed of batteries, battery management systems (BMS), energy management systems (EMS), power conversion systems (PCS), and other auxiliary facilities. Batteries are the core of the entire system, currently dominated by lithium batteries (such as LFP or NMC). The BMS is responsible for monitoring the voltage, temperature, and current of each battery cell, and balancing charging and discharging in real time to maintain the battery within a safe range. The EMS is a higher-level coordination management layer that can integrate load data, renewable energy generation, and grid conditions to dynamically allocate battery charging and discharging strategies. The PCS performs energy conversion between direct current and alternating current, such as inverters that convert the direct current of the battery into alternating current that can be used by buildings or the grid.

WT integrates products provided by multiple suppliers to propose modular solutions for large-scale energy storage systems for commercial and industrial use: the system uses several battery modules installed in racks or containers, and is assisted by fire protection / detection/ suppression/ control mechanisms, and then connected in series or parallel to form a larger capacity. Functional safety-rated microcontrollers are used to meet the needs of safety and microgrid integration. System on Chip (SoC) is used as the core of the system to improve the communication and processing performance of the energy management system.

In the promotion of modularization, WT modularizes battery packs and battery management systems (BMS), which can be flexibly stacked and configured according to applications. In addition, modular solutions are available for power conversion equipment, microgrid architecture, power meters, fire safety, and other protection and monitoring functions.

Participating in advocacy initiatives

WT collaborates closely with suppliers and customers, actively participating in green product and design initiatives, and prioritizing them in new product and application development.

In the semiconductor and electronic design industry chain, WT provided three core values:

Platform Integration: Serving as a bridge between suppliers and customers, facilitating collaboration

Technical Services: Providing technical services and promoting low-power, high-performance products and applications

Solution provider: Investing resources in researching clean technology-related products and applications, and providing solutions

In addition, WT actively participates in sustainable development seminars, engaging various industries (including transportation, rawmaterials, academic research, and petrochemicals). These conferences involve sharing the electronics industry’s net-zero goals and achievements, and exploring topics such as green energy, climate risks and opportunities, and carbon capture and storage. Through these actions, WT is committed to promoting the sustainable development of the industry.

Accelerating industry’s net-zero emissions through industry-academia collaboration

WT is dedicated to being a strategic partner to suppliers and customers. We have continuously invested resources to provide diverse technical services, assisting customers in quickly developing solutions and becoming a technical platform that delivers high-quality products and optimal solutions across various domains.

In pursuit of net-zero carbon emissions, industry-academia collaboration is crucial. WT actively promotes such collaboration through the following methods:

Information Sharing: Sharing real-world data from production, operations, and field applications, along with relevant data, to provide academic institutions with references for green design related to net-zero carbon emissions.

Technical Cooperation: Leveraging the academic community’s expertise and research resources in areas such as carbon capture, renewable energy, and carbon reduction technologies to accelerate technological innovation and research and development.

Talent Development and Resource Integration: Collaborating with suppliers and educational institutions to propose joint research projects, establish industry-academia programs, and participate in results presentations and exchanges, integrating the resources and strengths of academia and industry to accelerate the research, development, and application of carbon reduction technologies, and cultivate professional talent.

Through these efforts, WT not only promotes the sustainable development of the industry but also accelerates the realization of critical net-zero goals.

In 2024, facilitated an exchange visit to WT for international students from National Chengchi University, supporting international talent career development and promoting cross-border industry-academia collaboration.

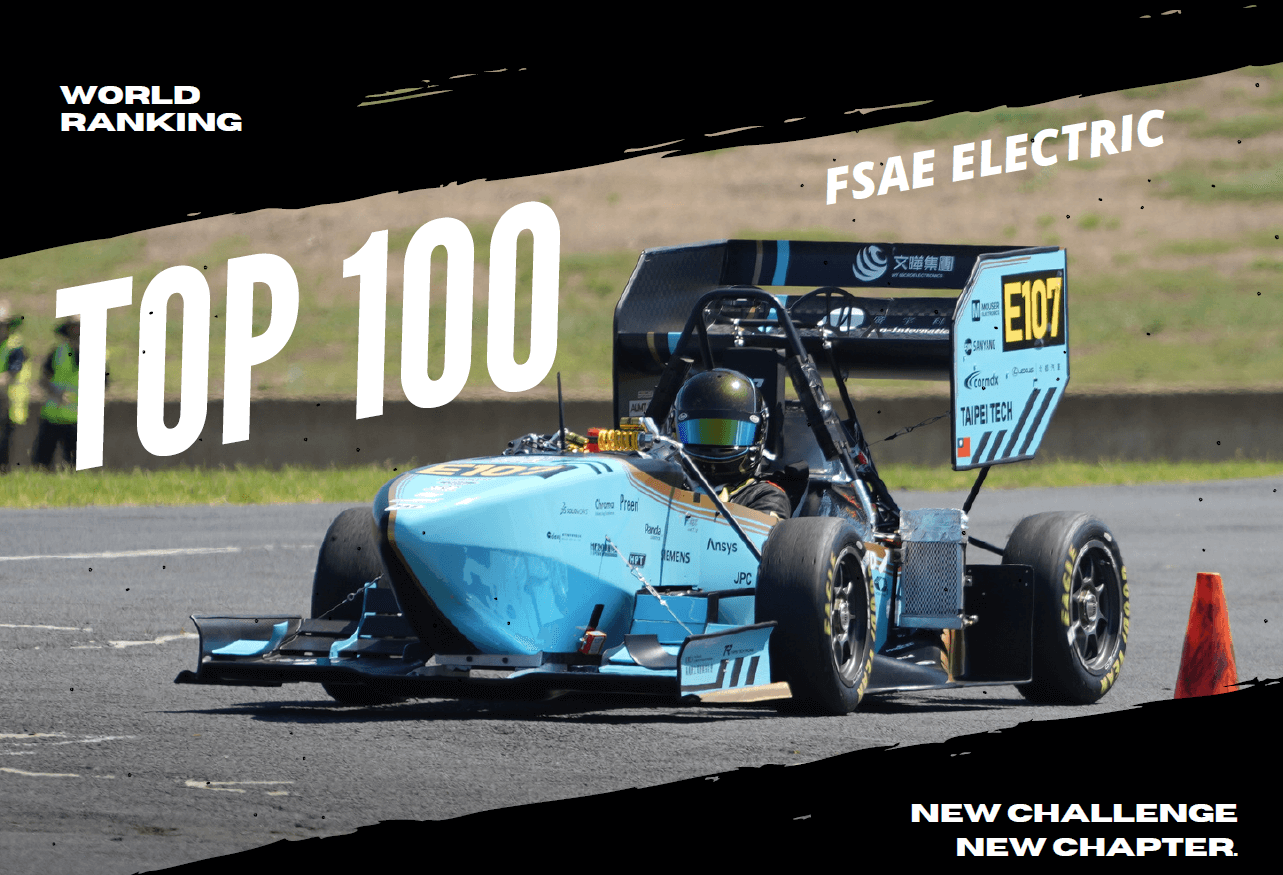

WT supports the National Taipei University of Technology’s commitment to practical engineering education, translating theoretical knowledge into practical operations and vehicle validation techniques, and deepening students’ understanding of technology and professional skills. In 2024, WT sponsored the National Taipei University of Technology Formula Racing Team to participate in the 2024 Student Formula Competition.

The Taiwan Student Formula League provides a platform for students to design and manufacture “Student Formula Cars” independently, and encourages exchange and learning among schools during the competition. Student Formula (FSAE) is not just a racing competition, but a comprehensive engineering and technology contest. The competition combines various fields: mechanics, materials, electricity, control, analysis, and business content such as marketing and business reports, all to train students to manage and build a small commercial-scale engineering team. The competition content is mainly divided into three parts: “design document review”, “on-site vehicle inspection”, and “track dynamic competition”. In 2024, the National Taipei University of Technology team achieved third place, and was the only team to stand on the podium for three consecutive years. In December 2024, the National Taipei University of Technology racing team also went to Melbourne, Australia to participate in the Formula SAE Australasia competition and successfully completed all inspections. To ensure smooth passage through static inspections, the team focused on preparing complete documents and familiarizing themselves with the rules and vehicle inspection procedures. As a result, they won the Best Vehicle Inspection Award from the competition judges and achieved an impressive 13th place overall. The National Taipei University of Technology Formula Racing Team’s world ranking has also moved up to 99th place following the success of the Australian competition.

Improve the past, change the future

As a leading semiconductor distributor, WT collaborates with hundreds of suppliers to serve tens of thousands of customers worldwide, jointly driving product and application innovation, improving lives, and shaping the multi-faceted future of the semiconductor industry in areas such as environment, society, education, economy, technology, and safety.

Review and Collaboration:

-Continuously collaborate with suppliers and customers to expand energy consumption and carbon footprint inventories

-Ensure suppliers provide green products that comply with regulations

-Collaborate with customers to reduce waste and adopt energy-saving technologies

Short-Term Plan:

-Actively distribute and promote green products

-Invest in research and development of forward-looking sustainable green solutions to drive industry green transformation

Mid-Term Plan:

-Continuously participate in green initiatives, implementing green design concepts in various applications

-Pursue environmentally friendly designs, providing low-power, high-performance chips and solutions

Long-Term Plan:

-Continuously disclose sustainable supply chain audit results and respond to carbon footprint inventory requests

-Collaborate with customers on inventory management to extend product lifecycles

-Collaborate with suppliers to strengthen global logistics and reuse plans, achieving waste reduction and a resilient future

High energy use, high efficiency needed

Artificial intelligence (AI) has experienced continuous development in recent years. Whether it’s machine learning, deep learning, or generative AI, coupled with the increasing accessibility and easy to use. AI’s integration and fusion across various industries has been promoted. For instance, AI is utilized to assist medical procedures and new drug development in health and preventive medicine. In financial management and economic activities, AI enhances customer experience and strengthens risk management. In manufacturing and retail, AI automates production and improves quality management through intelligent solutions. In personal transportation and logistics management, AI assistance makes transportation safer and more efficient.

All these conveniences and changes brought about by AI originate from semiconductor components. However, for AI to deliver accurate and effective functions, it requires training and inference capabilities. Comparing the power consumption differences between AI servers and traditional servers, traditional servers typically consume between 300 to 1500 watts, while the addition of AI accelerator GPUs or TPUs significantly increases power consumption to over 2000 watts.

WT recognizes the highly promising and forward-looking of AI. However, technological development must incorporate environmental sustainability as the foundation of all designs. Therefore, we have collaborated with suppliers and customers to propose three solutions to address the high energy consumption of AI servers:

1.We have designed a 3000-watt power supply for servers based on advanced control technologies and high-efficiency electronic components. 2.In collaboration with computing units such as CPUs/GPUs/TPUs/ASICs, we provide core power solutions with high energy efficiency to meet their computational demands. 3.In partnership with thermal management and cooling technology companies, we provide microcontrollers with communication and management functions to efficiently reduce system power consumption by dissipating heat generated by high-performance hardware.

In 2024, research and development investment reached NT$851 million. WT commits to continuously investing in clean technology R&D resources, aiming to increase R&D expenditure to NT$1 billion by 2030. WT focuses on the development and advancement of areas such as green energy, energy storage, and efficiency. Clean technology-related (low-carbon products) revenue reached 14.07% of total revenue,increased 2.64 percentage point compared with previous year. WT is targeting to achieve the goal of 20% clean technology-related revenue contribution by 2030.

An increase in Research and development (R&D) spending in 2024 for the fifth consecutive year (in NTD million)

|

|

Investing in solar plant developer and serving as a representative director

WT invested NTD 12.5 million in Daypower Co., Ltd. in April 2023. WT owns 10% shares of Daypower and serves as a representative director. WT participated in cash capital increase of Daypower and invested NTD 12.5 million in August 2024. WT maintains 10% shares of Daypower and accumulated investment amount reaches NTD 25 million. Daypower is a solar plant developer and completed 3.24 MW installation in 2024. Self-held solar plant reached 3.00 MW installation accumulatively in 2024, which generated 3.75 million kwh in 2024, equaling to 1,853 ton CO2 reduction.