WT upholds the core philosophy of “protecting employees and preventing hazards.” In 2024, the proportion of employees who underwent risk assessment across the entire group was 30.6%, including 1,249 employees from WT Taiwan Headquarters and 1,187 employees from Future Electronics’ EMEA region.

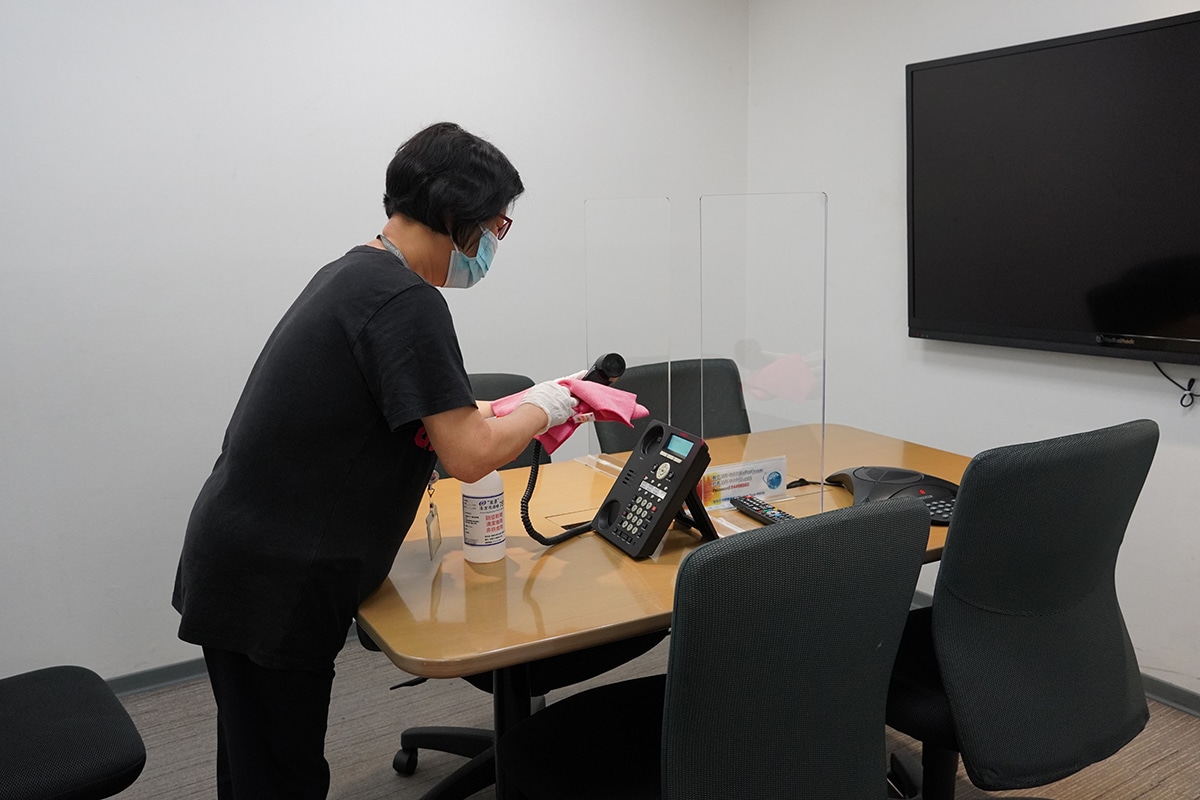

In Taiwan, we implement an occupational safety and health system in accordance with the Occupational Safety and Health Act, appointing dedicated occupational safety and health management personnel, fire safety managers, and first-aid providers.

Furthermore, we’ve legally established an Occupational Safety and Health Committee, comprising occupational safety and health management personnel, departmental managers, supervisors, technical engineers related to occupational safety and health, medical personnel providing labor health services, and labor representatives, with employee representation at 30%. In 2024, the committee convened four times. We also adopt a PDCA (Plan-Do-Check-Act) goal management process to regularly analyze potential dangers and hazards in the work environment, taking preventive measures against hazard types that may arise during operational procedures.

Prevention and management: Comprehensive safety measures

WT not only complies with the local fire safety regulations of each operating site but also tailors safety countermeasures to different work models in various locations, establishing comprehensive protective facilities. Our fire prevention management includes inspecting fire sources, evacuation facilities, and fire safety equipment. We regularly test, maintain, and service safety equipment and conduct fire drills to prevent incidents.

Rigorous evaluation: Activation only upon safety compliance

Before commencing any construction projects, WT conducts a complete safety assessment, requiring the signing of a safety and health commitment letter. We also plan escape route guides, fire suppression systems, monitoring equipment, and integrated fire and security systems. Only when all aspects comply with regulations upon completion is a usage permit granted.

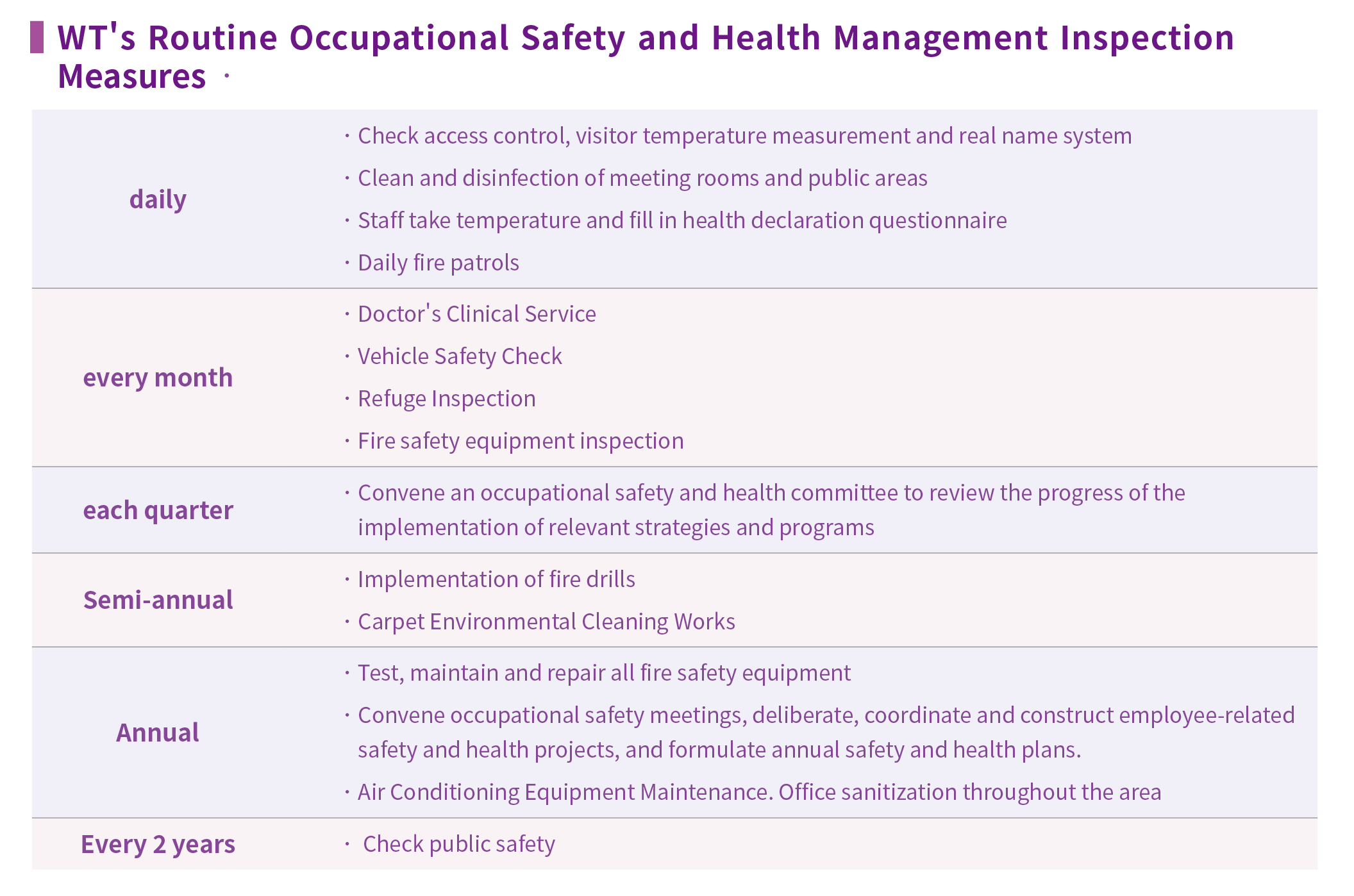

| WT Group: Routine Occupational Safety and Health Management Measures |

|---|

|

・Access control system management; visitors must exchange passes and register for restricted areas. Note: All operating sites adhere to local regulatory requirements, implementing management measures at varying frequencies. |

|

When contractors are tasked with projects at our operating sites, they are required to sign a “Safety and Health Commitment Letter.” This ensures that all construction activities adhere to the Occupational Safety and Health Act, thereby safeguarding the safety and well-being of their personnel. Furthermore, contractors must comply with WT’s “Code of Ethics and Professional Conduct,” and ensure that their staff deployed to WT facilities have received relevant ethics education and training. |

Regular drills enhance employee safety training

To ensure all employees in WT Taiwan are thoroughly familiar with occupational safety and health regulations and the company’s safety and health management mechanisms, we regularly provide safety education training and drills. Occupational safety and health management personnel, fire safety managers, and first-aid personnel all undergo regular refresher training as required by law. In 2024, this included: First-aid personnel safety and health on-the-job training, 3 hours for 6 participants; Fire safety manager refresher training, 6 hours for 2 participants; Occupational safety and health management personnel safety and health on-the-job training, 12 hours for 1 participant.

Continuous emphasis on workplace safety and employee safety awareness.

WT (excluding Future Electronics) reported zero disabling injuries across all operating bases throughout the year. Therefore, the occupational injury deaths, disabling injuries, total case incident rate (TRIR), and lost time injury rate (LTIR) were all zero. No work-related deaths or injuries were reported in 2024 among suppliers and contractors who worked in WT’s offices or logistics centers either, with thus 0 TRIR and LTIR.

Accident Notification Flow Chart

Notify labor inspection authorities within eight hours

Notify competent authorities and unit heads