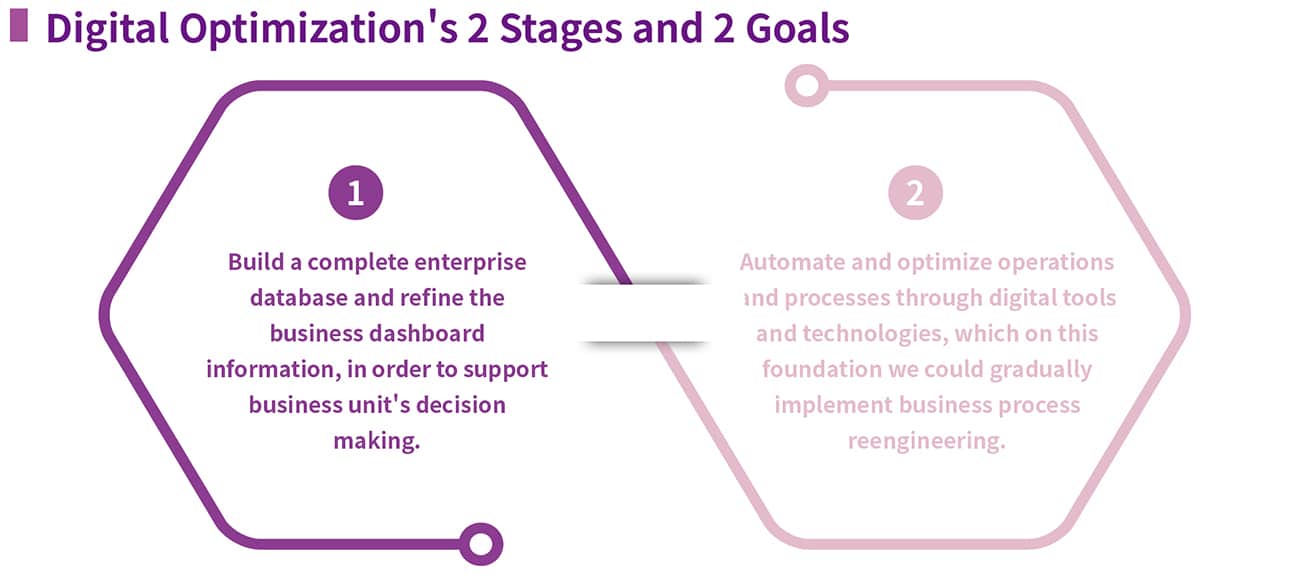

Digital optimization not only improves operational efficiency but also reflects our dedication to delivering low-carbon solutions.

Continually enhancing digital transactions and information exchange

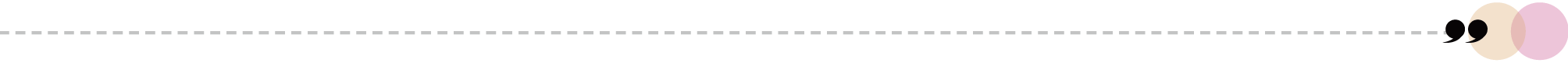

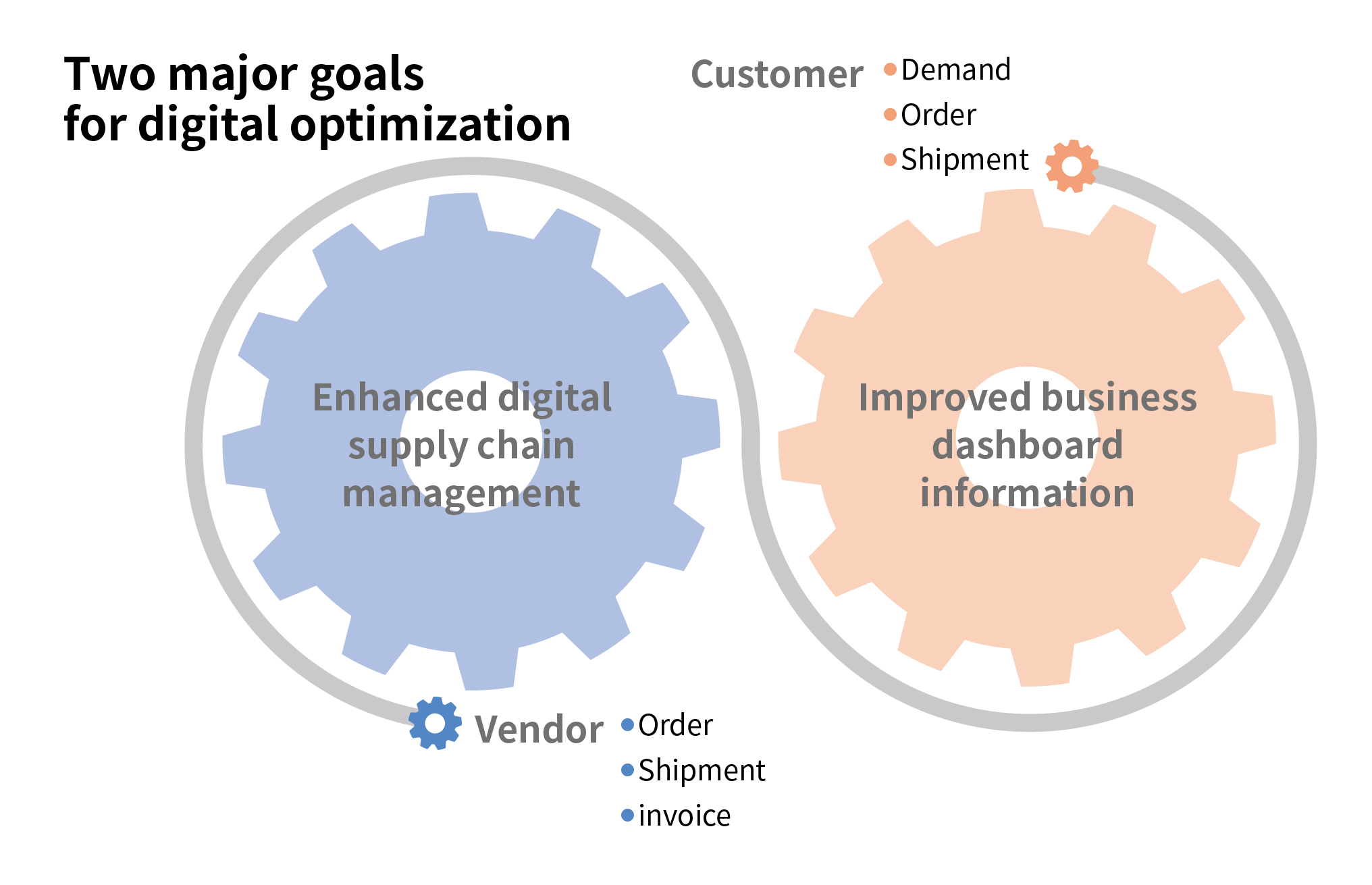

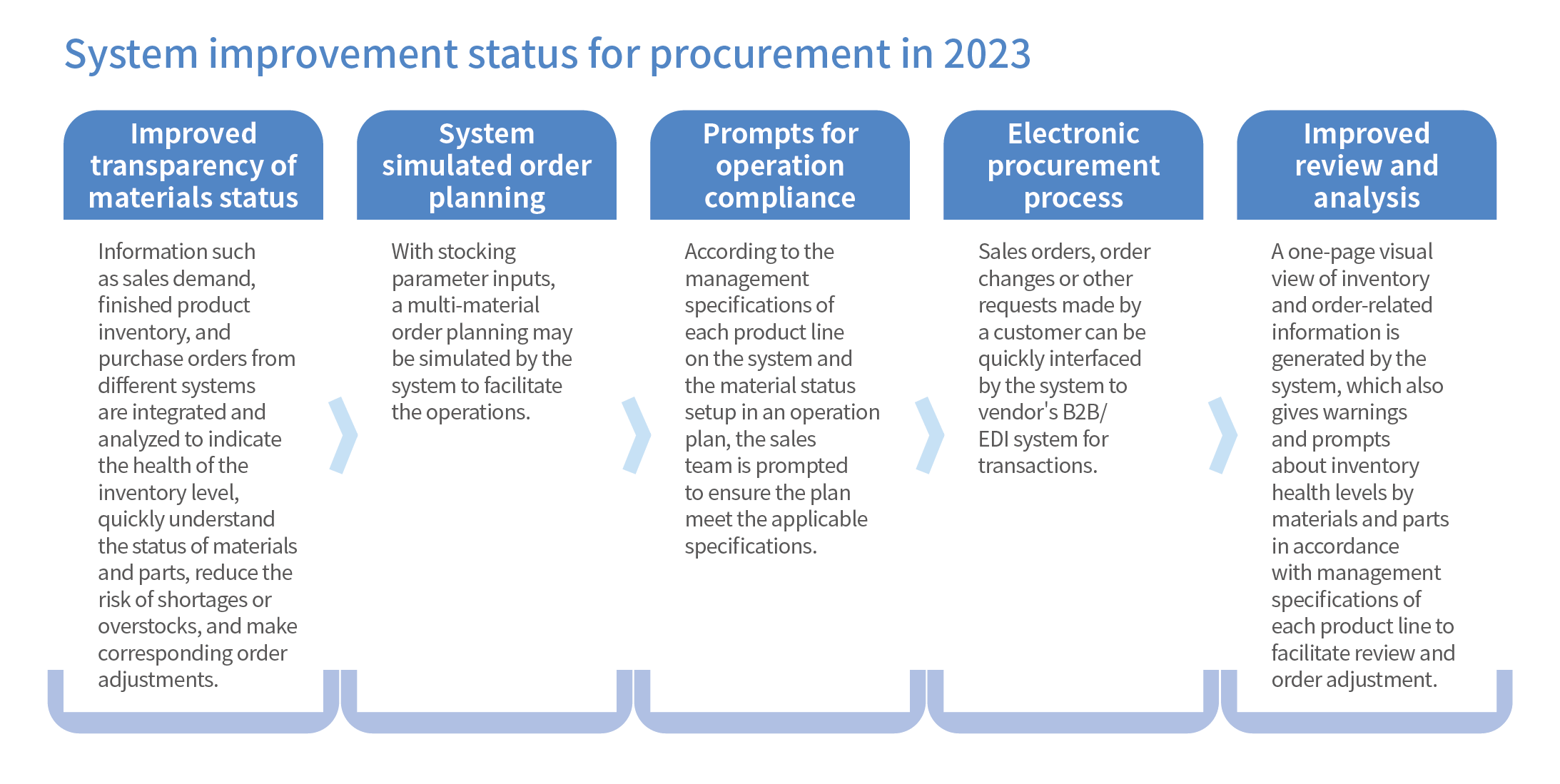

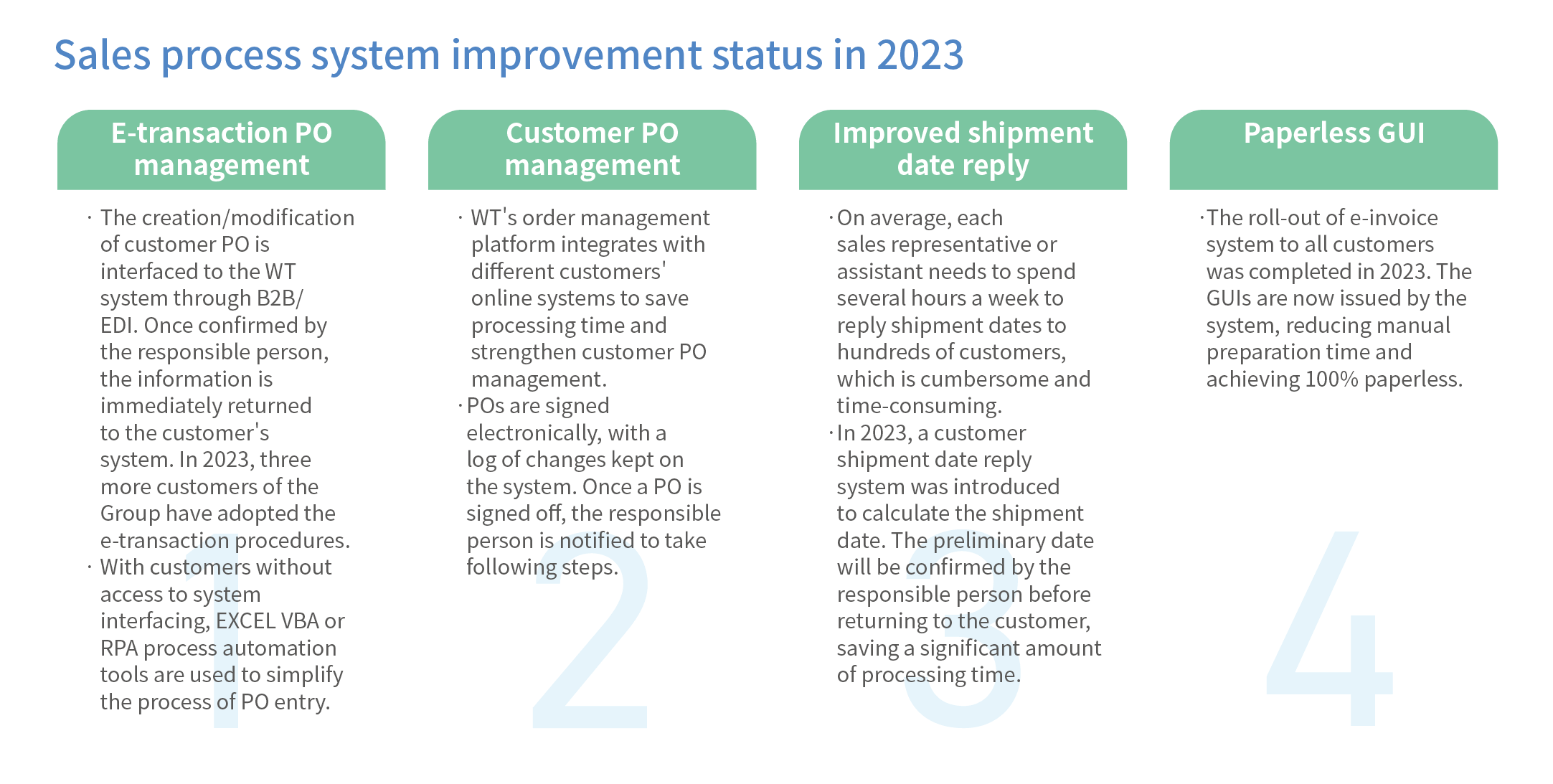

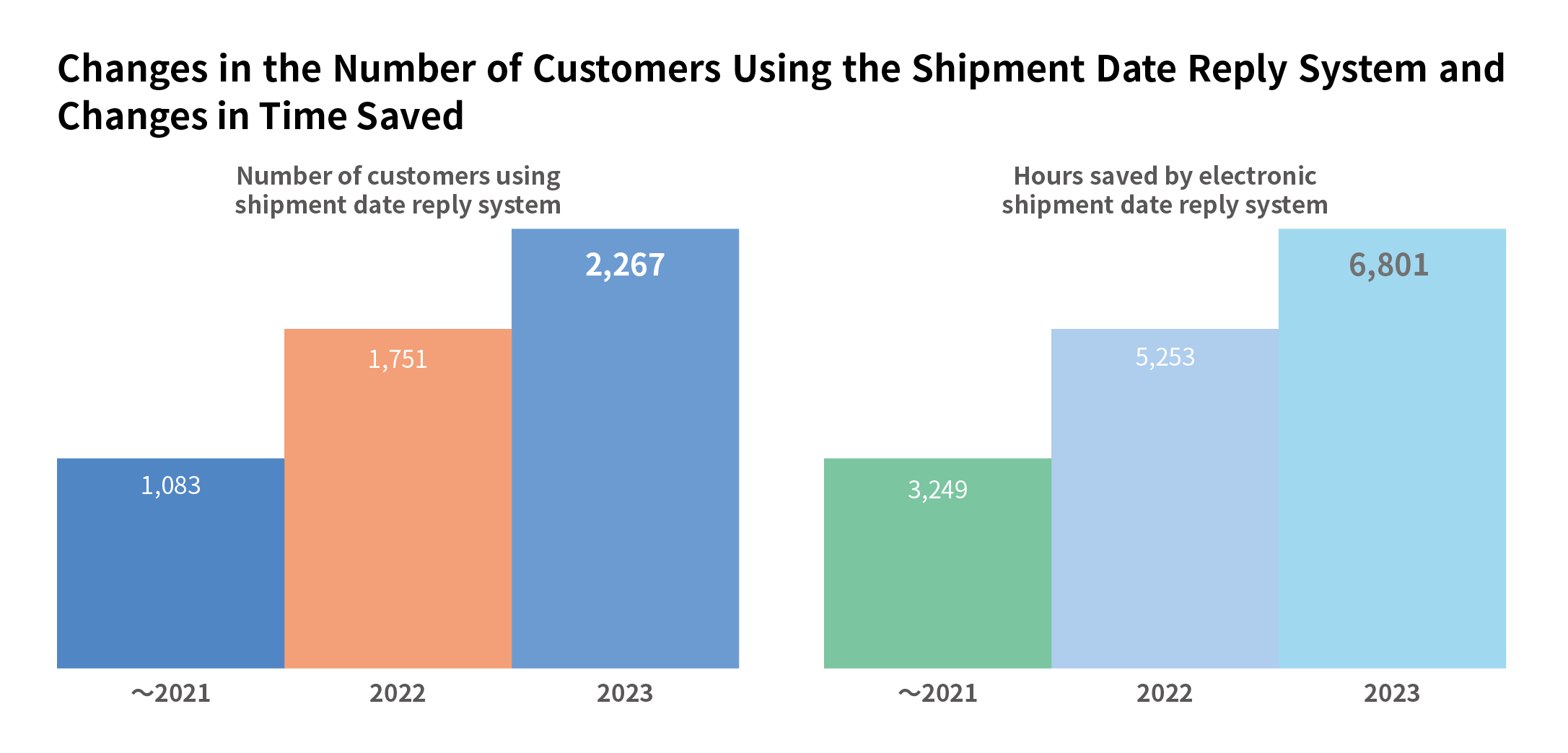

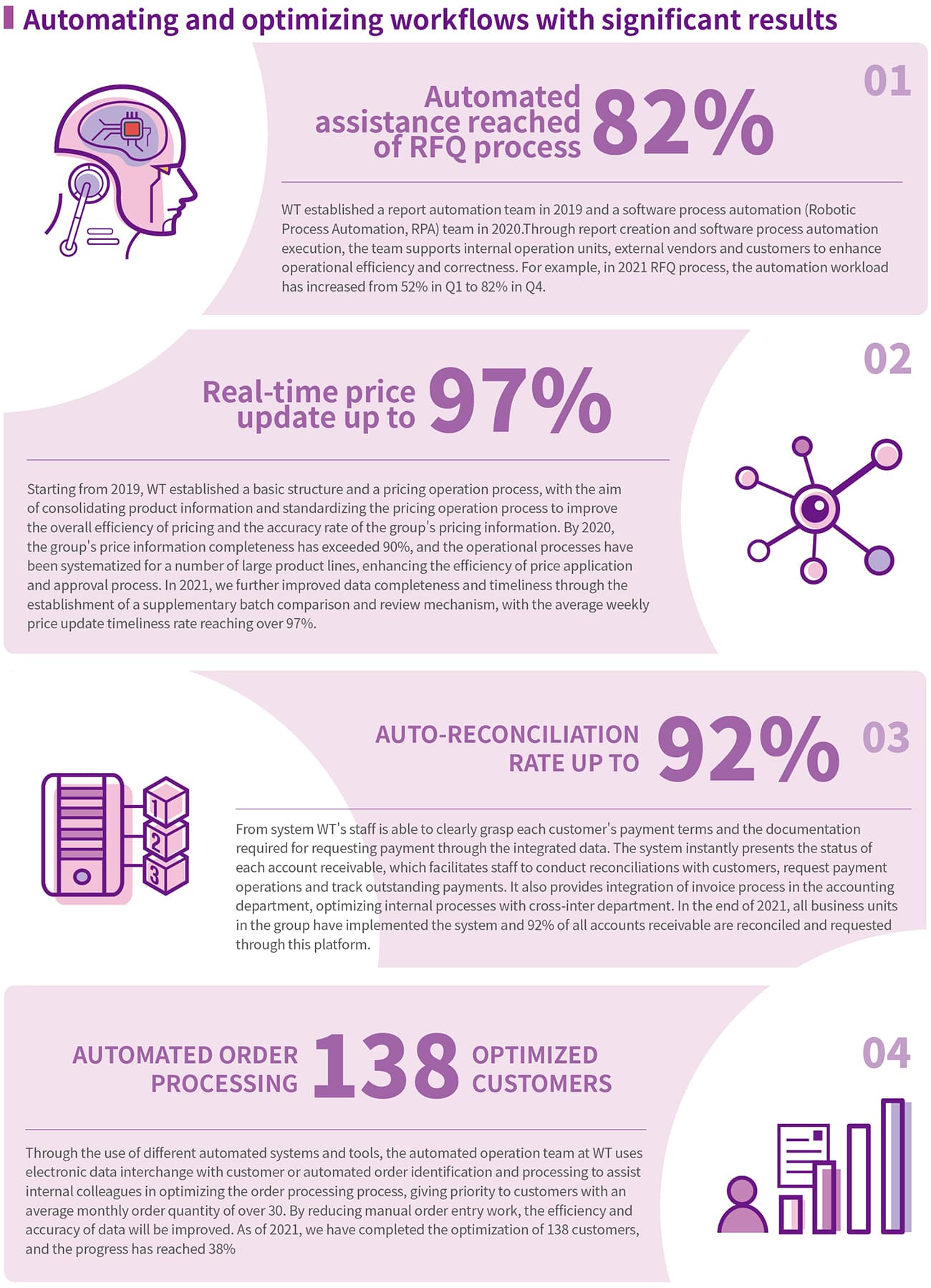

WT serves over 25,000 customers and suppliers. By adopting a digital transaction and data exchange operating model, the company significantly enhances employee efficiency across sales and procurement operations. This includes functions such as sales forecasting, customer order creation/modification, delivery schedule responses, and other related processes. These operations are integrated through mutually agreed-upon electronic data interchange (EDI) protocols. In addition, various automation tools are implemented to support manual tasks, aiming to streamline processes and improve overall management efficiency.

• In 2024, seven new corporate clients were onboarded to the digital transaction process.

• Approximately 6.2% of customers can now access delivery information directly via the website.

• As of 2024, over 89,902 tasks have been completed for 10 customers, with the number steadily increasing.

• Achieved 100% paperless processing.

• Ongoing process optimization is carried out based on individual customer requirements.

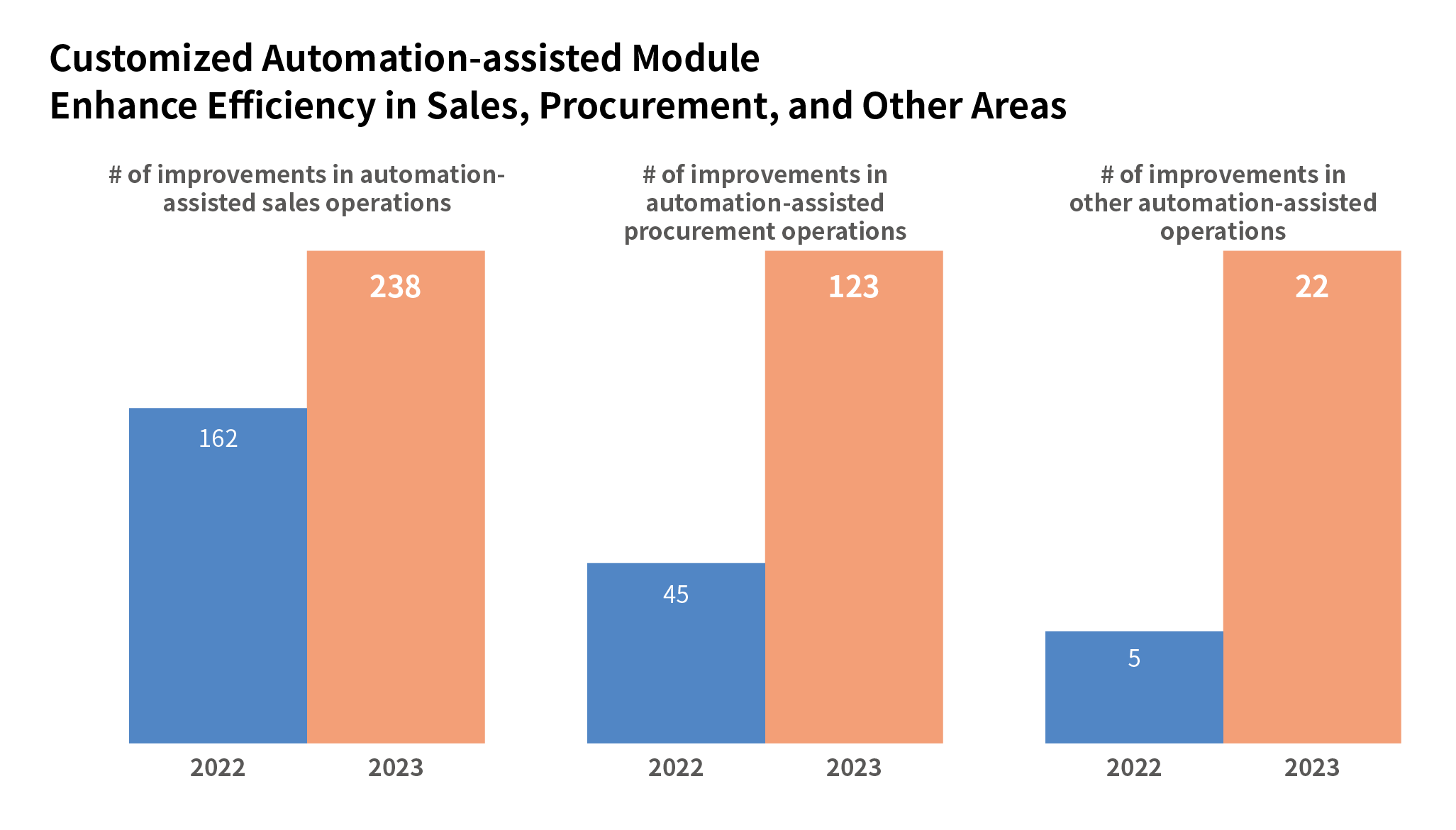

Software-assisted automated custom reports to streamline operations and enhance management

In recent years, beyond focusing on enhancing the systemization of supply chain management, the company has also introduced customized automation support modules. Using Excel VBA tools, employees can efficiently convert data into tailored reports, significantly improving work efficiency and value. This practice has become a routine part of daily operations. These tools have been increasingly applied across various functions, including sales, procurement, and other operational areas, contributing to continual improvements in reporting and workflow efficiency year after year.

Number of Improvements via Sales Automation Support Modules

Number of Improvements via Procurement Automation Support Modules

Number of Improvements via Other Automation Support Modules

Plans are in place to begin adopting AI to assist with rapid data identification and extraction.

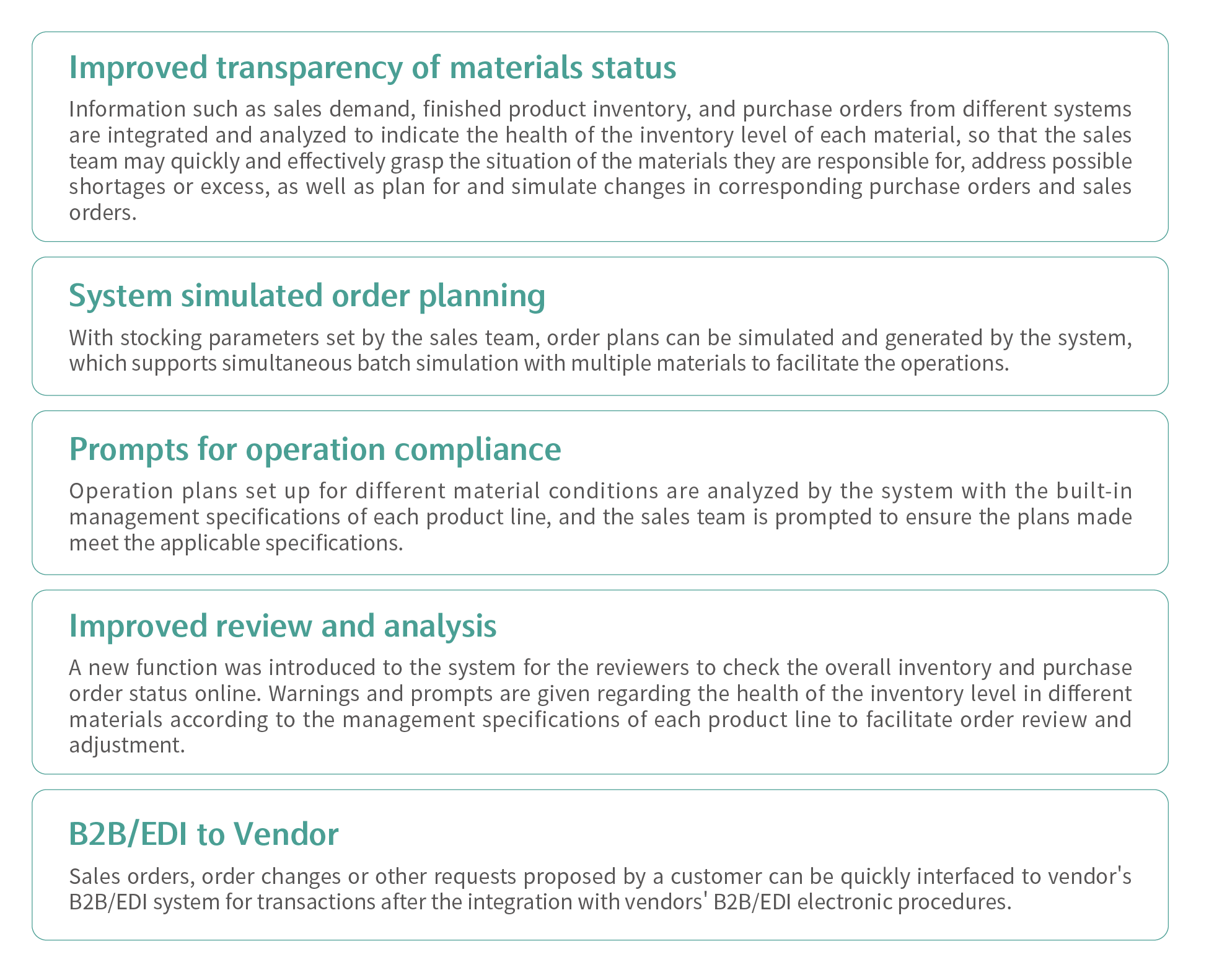

Scope Expansion of Procurement Process Applications

• Rolled out to all business units across the group to strengthen procurement management operations.

Customized Format Automation with Software Support

• Introduced automated modules for customized formats using Excel VBA tools to accelerate the conversion of procurement order changes and delivery date requests into customer-specific formats.

Digital Procurement Transactions

• Continued expansion of B2B/EDI transactions with customers and original suppliers, enabling electronic handling of sales order changes and related processes, with systemized, rapid submission to original suppliers.

Automation of Price Maintenance Operations

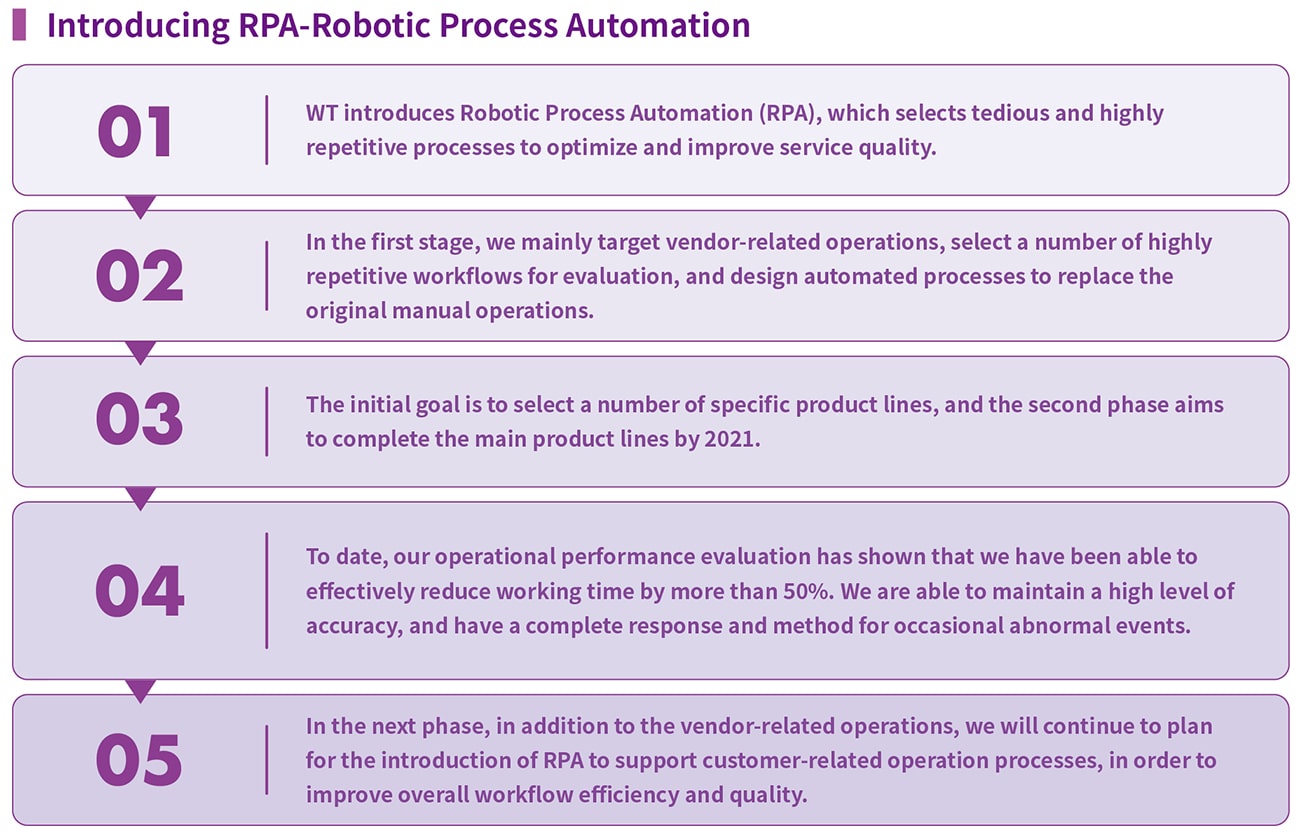

• Deployed RPA (Robotic Process Automation) to assist in maintaining procurement pricing information efficiently.

Integrating software automation into procurement systems for enhanced efficiency

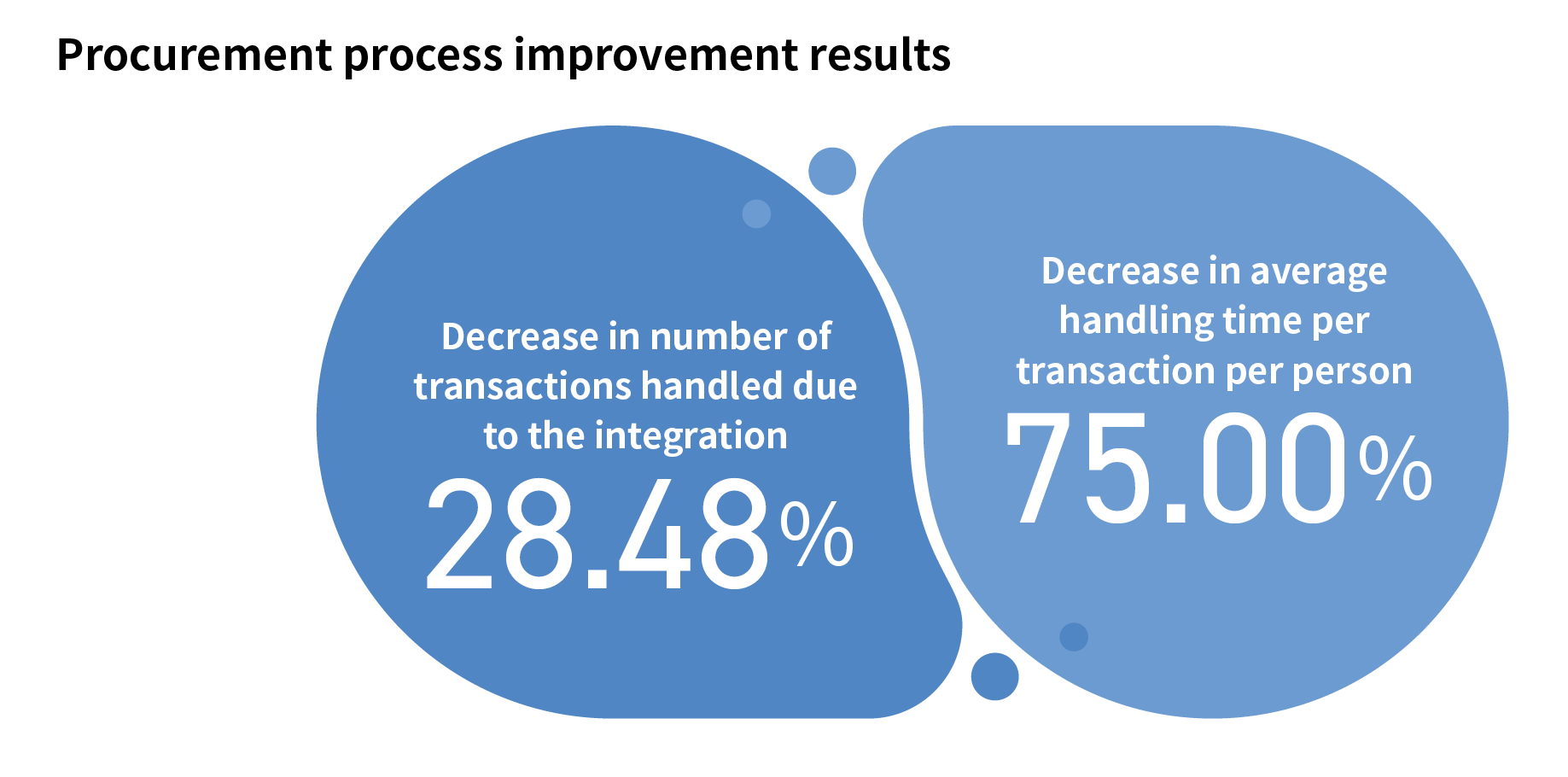

The procurement process and order management system enhancements implemented in 2023 have demonstrated significant operational results by 2024. Procurement orders and delivery schedule adjustment requests generated from the process are now integrated with automated support modules using VBA tools to handle customized formatting. This has substantially reduced the number of manual tasks and the time required for order processing.

Customization Rate of Procurement Order Format

Customization Rate of Delivery Schedule Management Format

Note: The customization rate of delivery schedule management formats declined in 2024 due to the integration of Future Electronics into the system.

Procurement price maintenance automation – enhancing efficiency and management

Real-time maintenance of procurement pricing data is a critical element of effective supply chain management. In 2024, the company expanded its digital optimization efforts into this area. While existing systems already support bulk updates by staff, Robotic Process Automation (RPA) tools were introduced to assist in routine operations. Currently, automated processes account for approximately 20% of procurement price maintenance activities. Broader implementation is planned for 2025, aiming to further improve operational efficiency and reduce manual workloads.

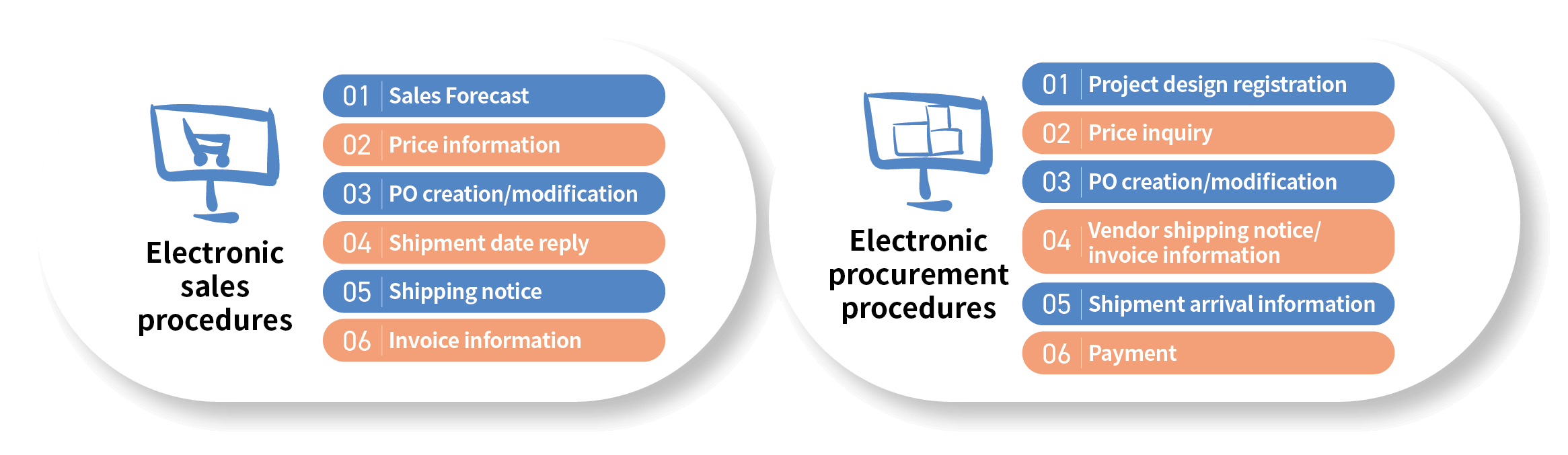

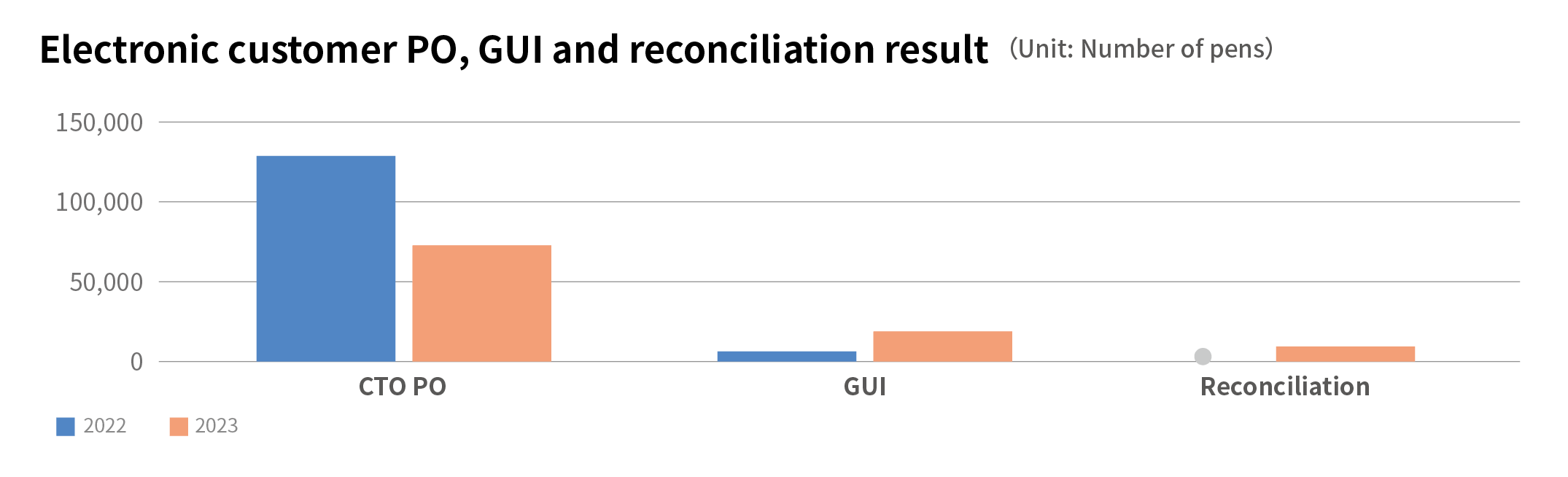

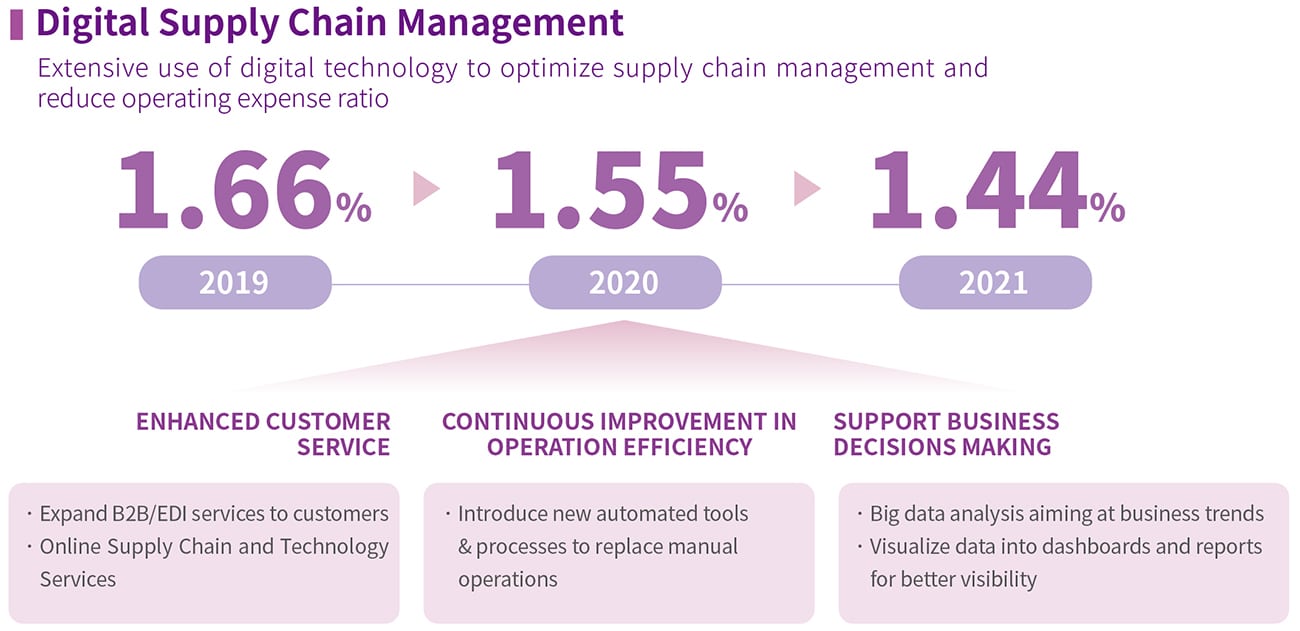

Demonstrating year-on-year improvement in digital transactions and information exchange.

With over than 10,000 customers and vendors, WT has introduced an operating model featuring electronic transactions and data exchange to significantly improve employee’s efficiency with digital sales and procurement procedures and with mutually agreed electronic exchange protocols that allow data interfacing. The following table shows the numbers of e-transactions with customers and vendors and their shares in revenue or purchase amounts in the past three years. Currently, 64% of the group’s revenue and 95% of procurement are handled through digital transaction models.

% of e-transactions in revenue from customers

% of e-transactions in purchase from vendors

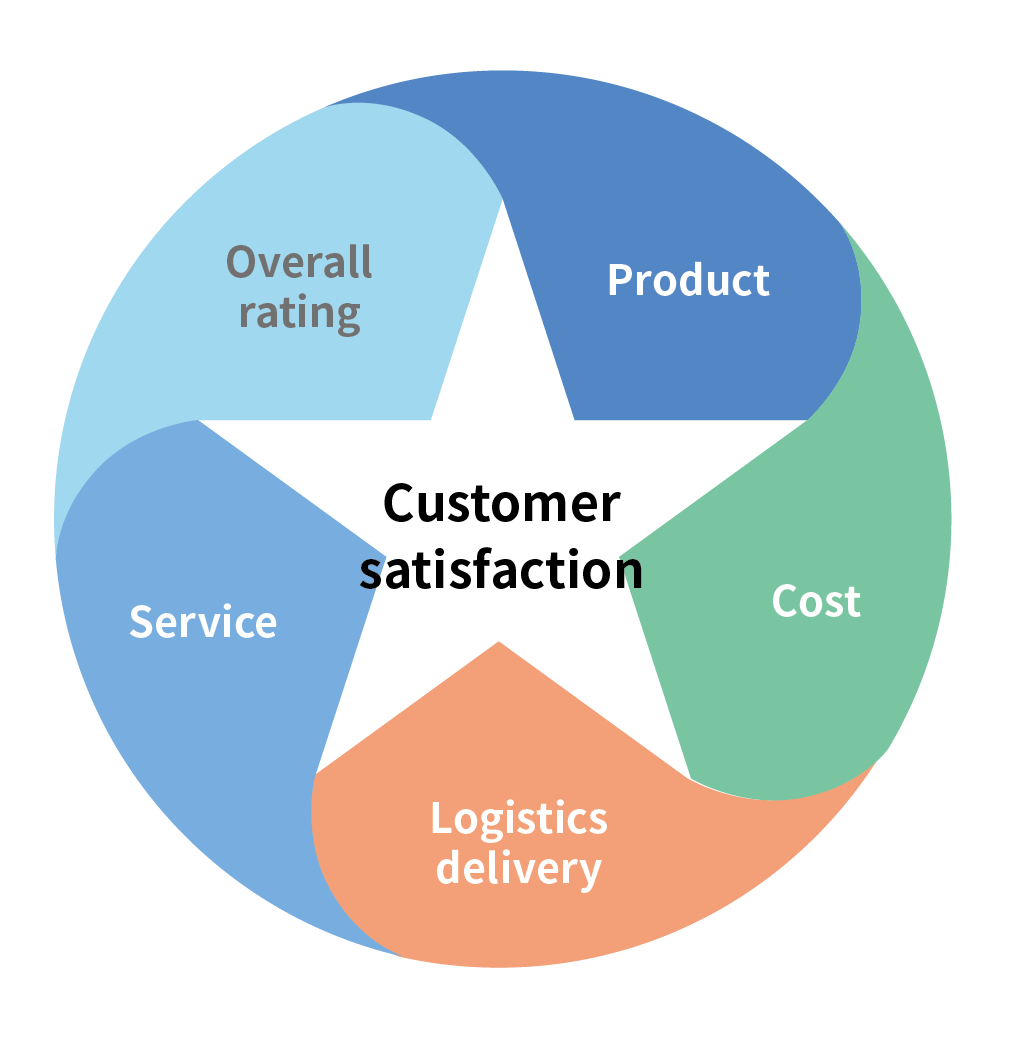

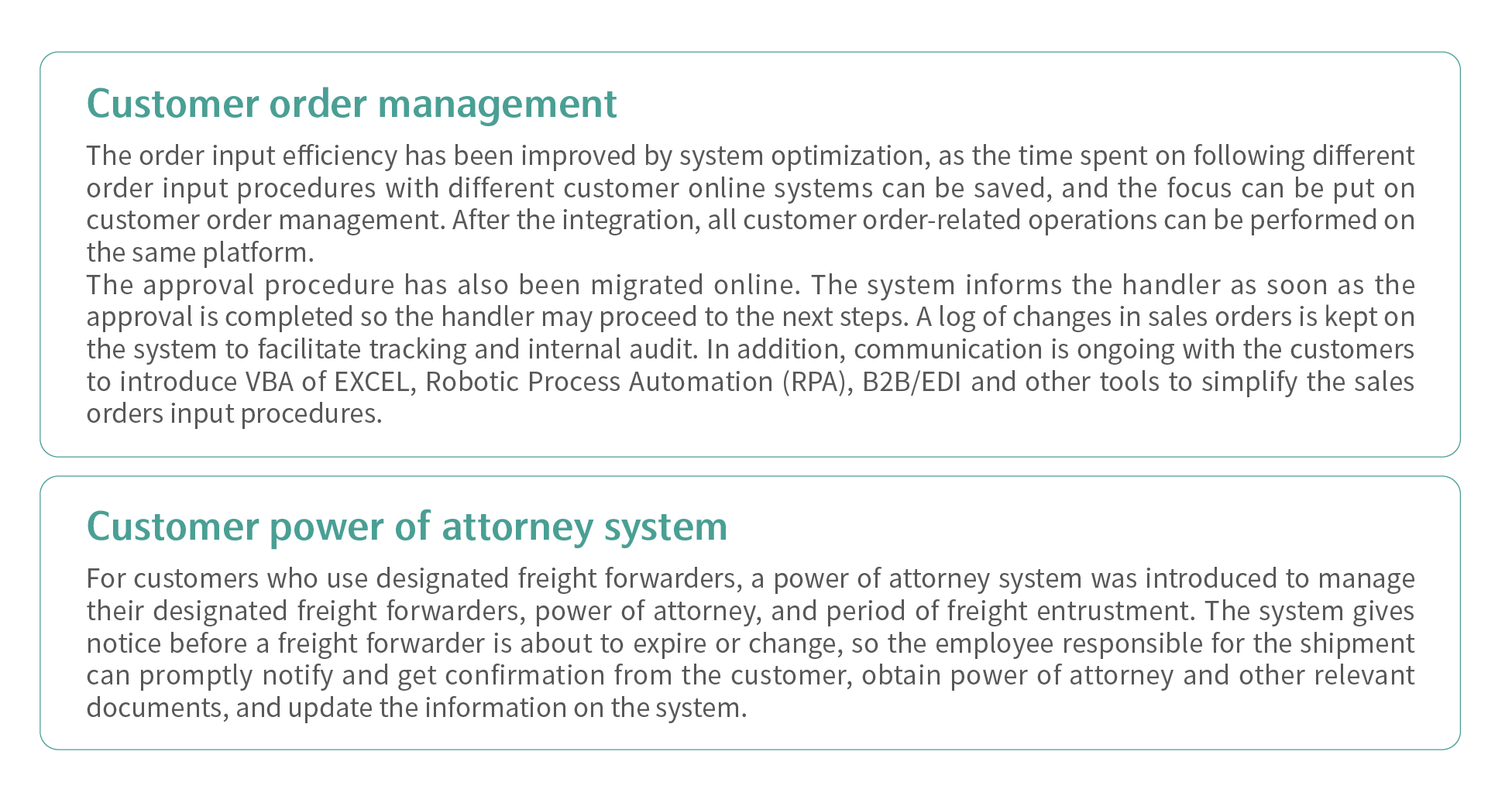

Providing customers with comprehensive services

Customer satisfaction in 2024 reached 89%.

WT’s sales representatives regularly communicate with customers about sales orders, shipment dates and other transactions related matters. There is also a customer complaint mechanism in place for customers to provide feedback about service quality, product shipment quality, or other abnormal events. In order to ensure the overall customer service quality, in 2024, a total of approximately 70 Customer Satisfaction questionnaires were sent to important customers and new customers (revenue coverage rate exceeded 65%). Customer opinions were collected through questionnaires, which will serve as an important basis for WT to continuously improve service quality. The survey results of the five major dimensions showed that 47% were very satisfied, 42% were satisfied, and the overall satisfaction rate was 89%.

The satisfied result for the five dimensions as below::

| Product | Logistics&Delivery | Price&Cost | Service | Overall rating |

|---|---|---|---|---|

| 93% | 91% | 72% | 94% | 94% |

Apart from the Price & Cost dimension, satisfaction in all other aspects exceeded 90%. Although satisfaction in the Price & Cost category was only 72%, when including responses classified as “acceptable”, the combined positive feedback reached 99.6%, with only 0.4% expressing actual dissatisfaction. Due to original suppliers’ pricing strategies, there is limited flexibility to influence changes in pricing.

The chart below shows satisfaction results across different dimensions:

In response to dimensions with lower satisfaction and topics of customer concern, we have followed up and implemented corrective actions. Feedback provided by customers has also been incorporated into our operational policies to drive continuous improvement and ensure service quality.

Highly Satisfied

Satisfied

Neither Satisfied nor dissatisfied

Dissatisfied

Highly Dissatisfied

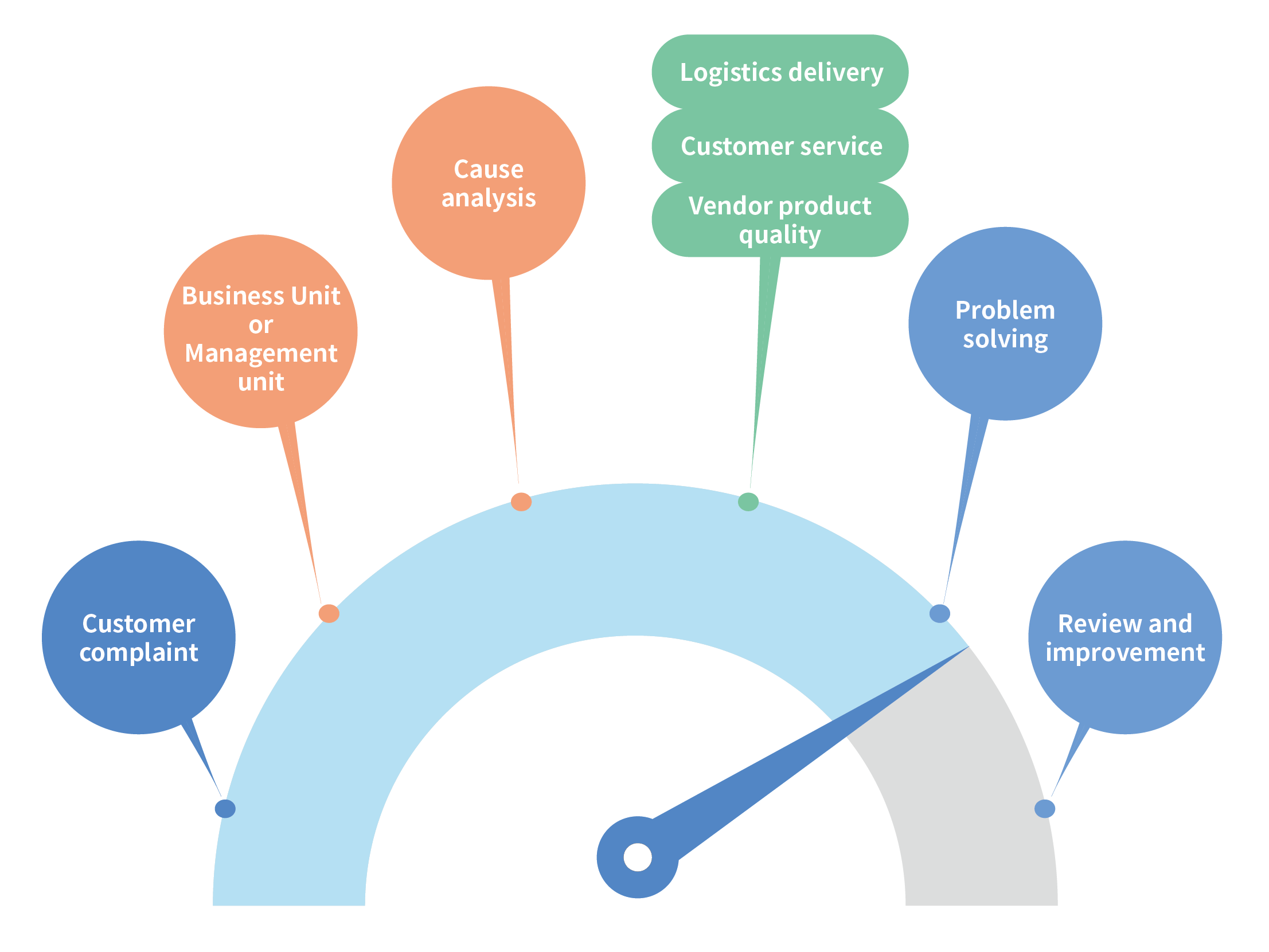

WT has already a customer complaint procedure in place to collect customer feedback about products and services. The complaints are filed to the competent units to analyze the cause, and keep track of improvements. Not only a reply will be given to customers about how the complaint is eventually handled, but internal publicity or training will be strengthened to prevent similar incidents from recurrence.

Customer complaint possible situations include: logistics delivery, customer relationship service, and product quality